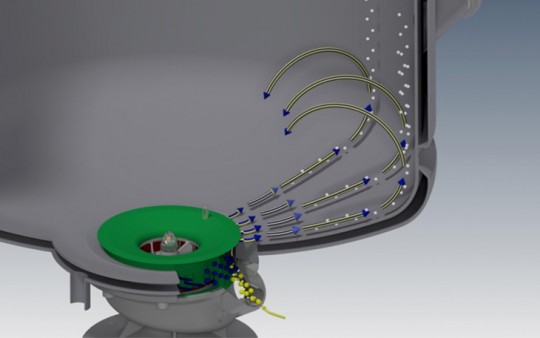

BECOMIX products offer a range of different options for the addition of raw materials in the form of powders. The Powder Jet homogeniser is one of the quickest and cleanest options available:

The patented Powder Jet is suited for the following applications amongst others:

RW 500 CD: Production with sterile and toxic ingredients Sterile powder supply directly in the mixer

RW 600 CD with integrated homogeniser. 400 litre pre-phase. Inline metering. Transfer lines. CIP/SIP.

LIM 400: Integrated turbo-dissolver and homogeniser in a single mixer. Heated direct transfer line to the filling line.

Main mixer RW 6600 S, several pre-phases, 4x  SV 6600 l product storage tanks, raw material dosing, recipe-guided control and CIP/SIP-automation (PROMAS CS Batch), storage tank managementsystem.

RW 600 CD with pre-phase MV 500 + MV 300. Fully automated and self-supporting CIP/SIP. Use of membrane valves for sterile processes

Main mixer RW 2.000 CD. Pre-phase MV 1.200. PROMAS CS Batch. Demineralised water dosing. Direct powder moistening below liquid level.

Main mixer RW 500 S. Sterile addition of raw materials. CIP/SIP. Atex zone 1.

Explosion prove zone 1. IQ/OQ. CFR 21 Part 11 software qualification. Recipe-guided control (PROMAS CS Batch). Total CIP.

Main mixer RW 2.500 CD. Powder Jet technology. Recipe-guided control (PROMAS CS Batch). Automatic raw material dosing. CIP/SIP.

Main mixer RW 2.000 S. pre-phase MV 400, MV 600. Inline raw material dosing. Inline process measurement. Sterile raw material supply.

Various devices with main mixer: RW 3.000, RW 2.500, RW 1.000. Pre-phase tank MV 1.000, MV 500. Simultaneous process thanks to automation.

LIM 60. One-pot procedure with a high degree of batch flexibility. Total CIP.

LVM 5.000 and LVM 10.000. Fully automated recipe-guided control (PROMAS CS Batch). Direct SLES dilution (cold process). Inline raw material dosing with tank farm. Paper-free documentation.

LVM 5.000 and LVM 10.000. Fully automated recipe-guided control (PROMAS CS Batch). Hot/ cold procedure for the fastest possible emulsifying process with large batches Inline raw material dosing with tank farm.

Main mixer RW 500 CD. Pre-phase MV 300 with CIP turbo dissolver Powder Jet technology. Total CIP.

RW 10.000 S. homogeniser ‚ÄúPlus‚ÄĚ. Hollow baffle. PROMAS CS.

RW 600 CD. Inline dosing of ammoniac in the shearing gap. CIP. PROMAS CS.

Main mixer RW 5.000. Pre-phase MV 5.000. Storage tanks 10 x 5,000. CIP/SIP. Total CIP. PROMAS CS Batch.

RW 250 CD. CIP. PromasCS. Powder Jet technology.

Large Volume Mixer ‚Äď BECOMIX LVM 10.000 l, LVM 3.000 l, Homogeniser, PowderJet, Hot/Cold, Vacuum intake and CIP Automation with PromasCS, Used for the production of Lotions.

Main mixer RW 600 CD. Pre-phase MV 250. PROMAS CS Basic. Demineralised water dosing.

Main mixer LVM 4.000. Pre-phase MV 3,000.

Main mixer RW 5000 CD. Pre-phase MV 2000. PROMAS CS Basic. Inline raw material dosing.

Main mixer MV 2.500. Pre-phase MV 2,000. Inline raw material dosing, inline filling line.

Main mixer RW 125 CD. PROMAS CS Basic.

MH 2.000 with MV 2.000. Homogeniser for wax emulsions. Turbo dissolver for wax melt.

Main mixer RW 3.000 S. pre-phase 2 x MV 1.500. PROMAS CS Batch. Total CIP.