PharmaceuticalA selection of specific applications processed by our customers from the pharmaceutical industry

RW 500 CD: Production with sterile and toxic ingredients Sterile powder supply directly in the mixer

Technologie

RW 600 CD with integrated homogeniser. 400 litre pre-phase. Inline metering. Transfer lines. CIP/SIP.

Produkte

Technologie

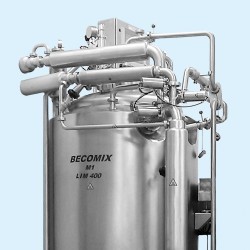

LIM 400: Integrated turbo-dissolver and homogeniser in a single mixer. Heated direct transfer line to the filling line.

Technologie

Main mixer RW 6600 S, several pre-phases, 4x  SV 6600 l product storage tanks, raw material dosing, recipe-guided control and CIP/SIP-automation (PROMAS CS Batch), storage tank managementsystem.

Produkte

Technologie

RW 600 CD with pre-phase MV 500 + MV 300. Fully automated and self-supporting CIP/SIP. Use of membrane valves for sterile processes

Produkte

Technologie

Main mixer RW 2.000 CD. Pre-phase MV 1.200. PROMAS CS Batch. Demineralised water dosing. Direct powder moistening below liquid level.

Produkte

Technologie

Main mixer RW 500 S. Sterile addition of raw materials. CIP/SIP. Atex zone 1.

Produkte

Technologie

Explosion prove zone 1. IQ/OQ. CFR 21 Part 11 software qualification. Recipe-guided control (PROMAS CS Batch). Total CIP.

Produkte

Technologie

Main mixer RW 2.500 CD. Powder Jet technology. Recipe-guided control (PROMAS CS Batch). Automatic raw material dosing. CIP/SIP.

Technologie

Main mixer RW 2.000 S. pre-phase MV 400, MV 600. Inline raw material dosing. Inline process measurement. Sterile raw material supply.