CosmeticsA selection of specific applications processed by our customers from the cosmetical industry

Various devices with main mixer: RW 3.000, RW 2.500, RW 1.000. Pre-phase tank MV 1.000, MV 500. Simultaneous process thanks to automation.

Products

Technologie

LIM 60. One-pot procedure with a high degree of batch flexibility. Total CIP.

Technologie

LVM 5.000 and LVM 10.000. Fully automated recipe-guided control (PROMAS CS Batch). Direct SLES dilution (cold process). Inline raw material dosing with tank farm. Paper-free documentation.

Products

Technologie

LVM 5.000 and LVM 10.000. Fully automated recipe-guided control (PROMAS CS Batch). Hot/ cold procedure for the fastest possible emulsifying process with large batches Inline raw material dosing with tank farm.

Products

Technologie

Main mixer RW 500 CD. Pre-phase MV 300 with CIP turbo dissolver Powder Jet technology. Total CIP.

Technologie

RW 10.000 S. homogeniser ‚ÄúPlus‚ÄĚ. Hollow baffle. PROMAS CS.

Technologie

RW 600 CD. Inline dosing of ammoniac in the shearing gap. CIP. PROMAS CS.

Products

Technologie

Main mixer RW 5.000. Pre-phase MV 5.000. Storage tanks 10 x 5,000. CIP/SIP. Total CIP. PROMAS CS Batch.

Products

Technologie

RW 250 CD. CIP. PromasCS. Powder Jet technology.

Technologie

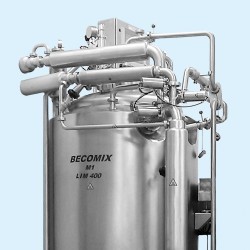

Large Volume Mixer ‚Äď BECOMIX LVM 10.000 l, LVM 3.000 l, Homogeniser, PowderJet, Hot/Cold, Vacuum intake and CIP Automation with PromasCS, Used for the production of Lotions.

Products

Technologie

Main mixer RW 3.000 S. pre-phase 2 x MV 1.500. PROMAS CS Batch. Total CIP.